Why hemp underwear?

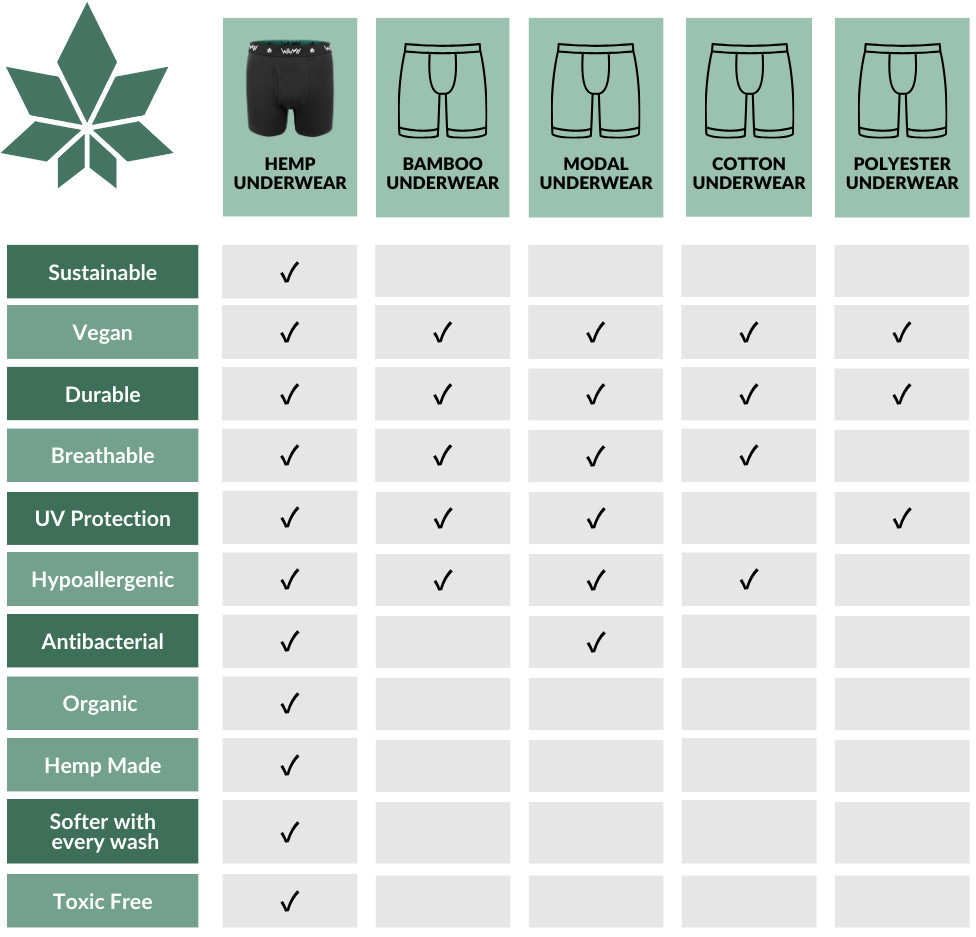

Hemp fabric is naturally anti-bacterial, with anti-odor properties. Super comfortable, breathable and gets softer with every wash. Hemp is also organic, eco-friendly and can help save the planet. Hemp is the perfect fabric for your underwear. Why Not Hemp?

BEST SELLERS

Hemp fabric is #1 in Sustainability.

WAMA is #1 in Hemp Underwear.

Organic Underwear that is good for you and the planet 🌎

subscribe & save 15%

Subscribe today and get a whooping 15% off your first order with us along with exclusive sales, latest drops & many more.