Fabric Testing: All You Need To Know

|

If you're not happy with your first pair of underwear after trying it on, let us know.

We'll send a new size or color, or give you a refund. No returns needed.

Katie Lemon

|

Fabric testing is so incredibly important in ensuring that consumers can trust the quality of the clothes they buy and wear. Hemp clothing brands like WAMA know just how important it is to rigorously test fabrics so that the final product is comfortable, durable, and made to the highest standard.

So what exactly is fabric testing, and what kinds of textile tests does WAMA use? Read to learn all about the journey hemp fabric goes through before becoming your next pair of high waisted underwear or hemp bra !

Fabric testing is an inspection process designed to evaluate the quality and composition of a textile. There are many different ways to test a fabric, and each test is designed to assess different factors of a high quality fabric. Some of the most popular forms of textile tests include:

Without properly testing a fabric, you can’t be sure that you’re getting the textile you think you are. In fact, over 80% of retail products on the market today have improperly labeled fiber content. When WAMA founder Shakib Nassiri first started the brand, he ordered 200 pairs of hemp underwear to be made. He had it independently tested, and was shocked to find out that the first batch of “hemp” underwear was actually made with linen!

When it comes to hemp vs linen , these two fabrics can often be nearly identical in texture and feel, but in fact linen just doesn't compare to the eco-friendliness of hemp. If WAMA hadn’t tested the fabric, we would’ve never known that those 200 pairs of underwear were actually linen. While this debacle delayed WAMA’s launch for a full year, we knew we had to deliver the best possible product—and that wasn’t going to be linen underwear mislabelled as hemp.

Unfortunately, mislabeling fabrics isn’t the only way that suppliers and other players in the fabric manufacturing chain will sometimes try to cut corners. Especially with how global the fashion industry is today, it’s important to always independently test fabric to make sure that the highest quality standards are being upheld, and the fabric is built to last.

Hemp fabric, especially made from hemp in China , is one such fabric that many suppliers try to cut production costs. Often, suppliers will:

Hemp is super sustainable compared to other fabrics, and making quality hemp fabric can be expensive. While cutting corners helps suppliers save money, it cheats consumers out of the high quality products they’re expecting to receive.

It’s better for the environment when faulty fabrics are found early on in the manufacturing process, as clothing manufacturers can ensure that only the highest quality fabric is made into final products. Over time, this cuts down on carbon emissions, energy usage, and money spent by weeding out low quality textiles before they’re made into clothing and other goods.

Not to mention, the higher quality a fabric is, the longer it’s going to last as an item of clothing. After all, the average American throws away a whopping 81 pounds of clothing every year. When you buy clothes made with tested and vetted fabric, you’re ensuring that the fabric is strong enough for regular wear, there aren’t any holes or other issues with the fabric, and therefore you can get a lot more wear out of the clothes you’ve bought.

All WAMA fabric undergoes an extensive textile testing process. First, hemp fibers are spun into fabric in a factory in China, then inspected for quality control using a 7-step physical inspection. Then, fabric is sent to an independent lab and tested for 3 different standards. Only after passing quality control and independent testing will fabric be sent to the garment factory to be made into WAMA underwear.

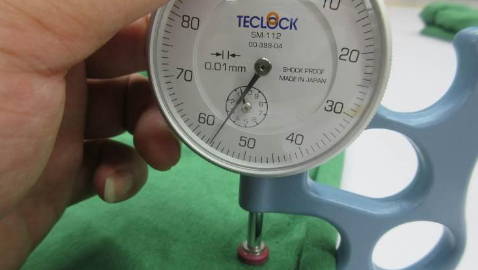

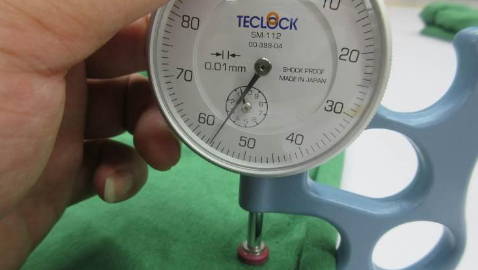

Once fabrics are ready, we hire AQF to visit our fabric supplier to physically execute on-site quality control of the material. Based on the testing, they send us a full quality control report. Once the fabric passes the physical QC inspection, they will cut a few pieces of the fabric to send to SGS for lab testing. All fabric samples must be inspected for the following qualities:

Once fabric passes physical inspection, it’s time for more textile testing at the lab. We use SGS Testing , one of the most trusted independent labs for inspection and verification worldwide. Because they’re entirely independent from WAMA, you can trust that the results are as accurate as possible. The following three standards are checked to ensure only the highest quality hemp fabric gets made into WAMA underwear.

The required fabric composition for WAMA hemp underwear is 53% Hemp / 44% Organic Cotton / 3% Spandex. When testing for fiber content, we accept only ±3% variation in this blend. Testing for fiber content can take up to 30 days and delays the production process, but it’s a step we never skip. By testing fabric composition, we can ensure customers get the highest quality hemp underwear possible.

For Full Transparency - Download Full Report Here .

Testing for color fastness ensures that the low impact dyes or natural color of your WAMA underwear won’t fade away from you wearing, washing, or sweating in them. Color fastness is tested by the lab in three ways:

For Full Transparency - Download Full Report Here .

This is the newest form of fabric testing we’re doing here at WAMA to ensure your hemp underwear is built to last through even the most rugged days and wildest adventures. For strength testing, all WAMA underwear is tested for tensile strength, tear strength, and bursting strength.

For Full Transparency - Download Full Report Here .

You can check out a recent set of lab results for both our black fabric here and WAMA green fabric here .

While all WAMA fabric is extensively tested using the steps above, there are even more tests that we do on our products to make sure you get the very best pair of thong underwear or triangle bralette possible.

That’s because hemp is a particularly special fabric, with all sorts of unique benefits that you won’t find in many other fabrics. And here at WAMA, we like to certify through independent lab results that you’re actually getting those unique benefits when you wear our products.

For one, hemp is perfect for naturally antibacterial underwear . It fights off mold and mildew, and we’ve got the test results to prove it. On top of that, hemp is one of the best options for upf fabric —without chemicals or additives, hemp blocks out harmful UV rays and protects your skin from the sun. And with our independent lab results, we feel good knowing you’re getting the very best hemp fabric available to protect your privates naturally.

Textile tests help clothing companies know that the goods they sell will be durable, comfortable, and made to the highest standard. Much of the fast fashion industry prefers to cut corners: using low quality fabric, not properly testing textiles, and producing clothes that are designed to fall apart quickly so you have to keep going back for more.

When you buy clothes that have been exhaustively tested throughout the manufacturing process, you can feel good knowing your clothes were constructed to the highest quality. Always look for brands that use third party testing to know that the sustainable fabrics you’re investing in are going to make it for the long haul.

Did you know the role fabric testing plays in sustainable fashion? Do you think you’ll consider textile testing when shopping for clothes in the future? Let’s chat about it in the comments!

Get updates on restocks, new color and size releases, and upcoming product launches. You’ll also get a 15% discount on your first order of hemp underwear.